Project overview

Client: Ibstock Brick

Project title: PLC UPS power failure back up supplies

Sector: Manufacturing Industrial

Project value: £50K

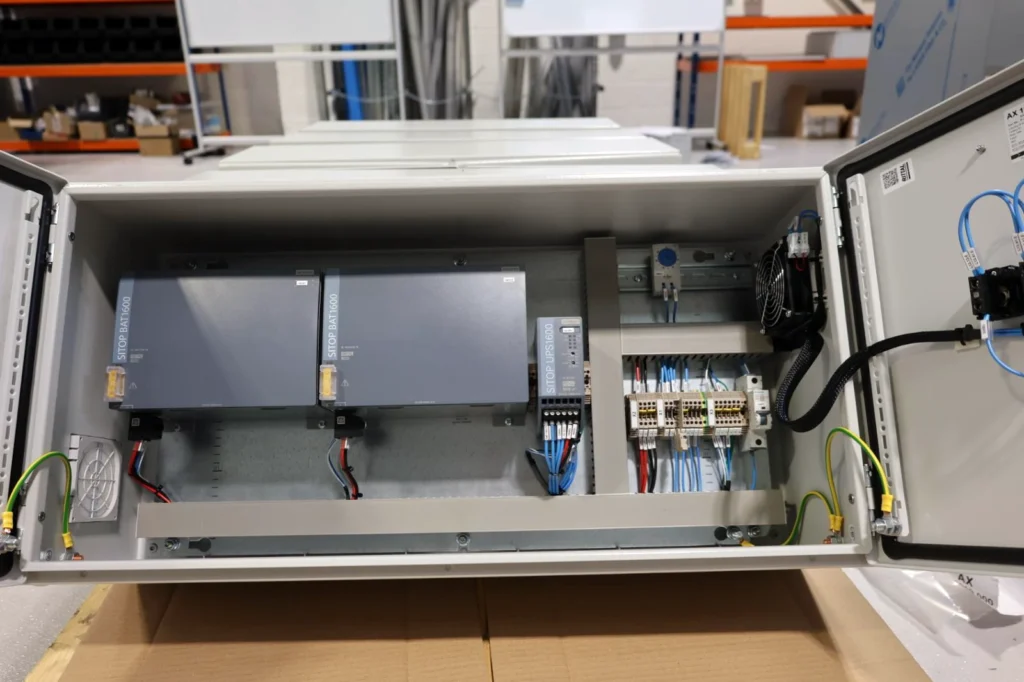

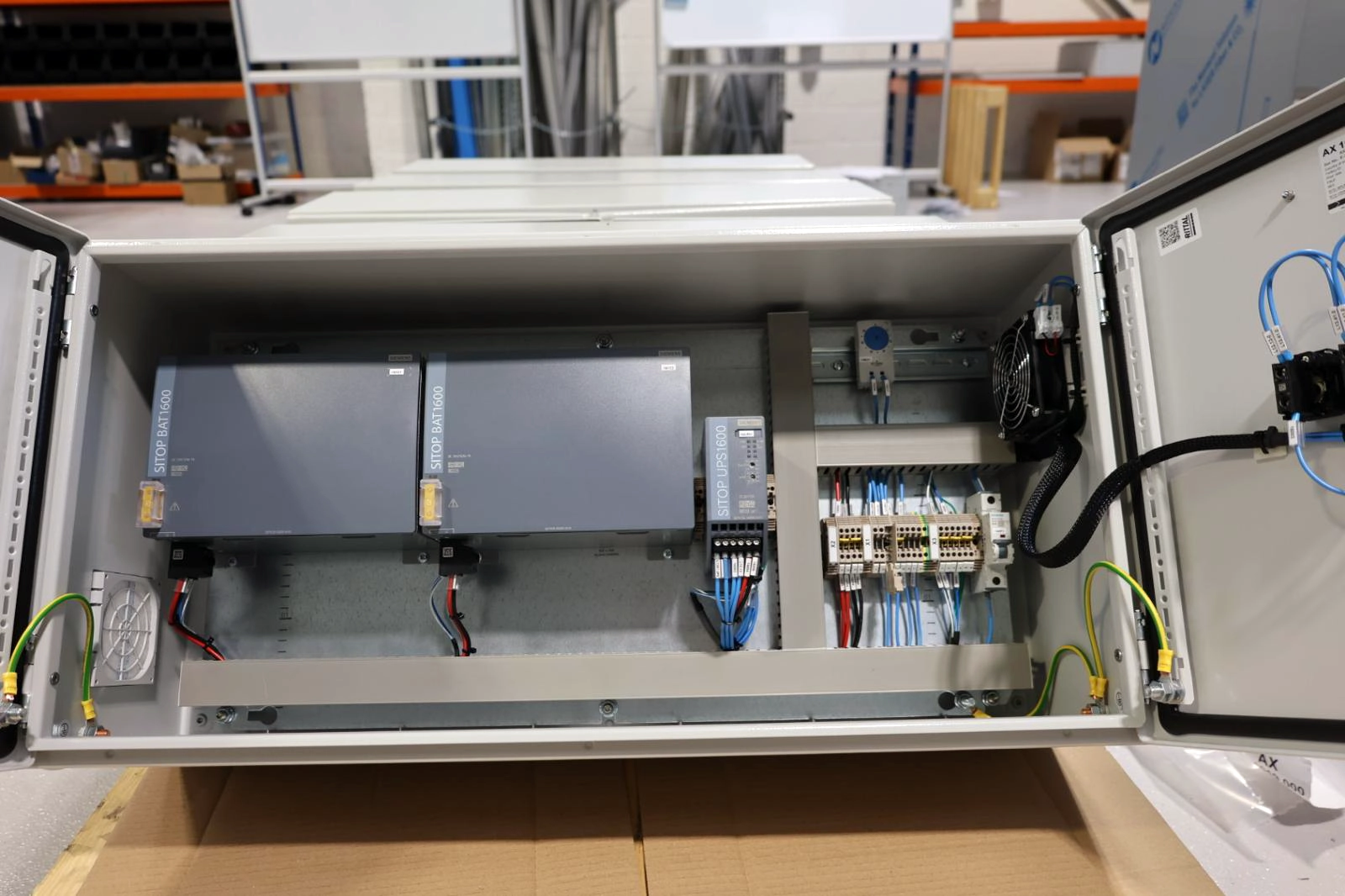

Interpanel services: Design, supply & installation of Uninterrupted Power Supplies (UPS) control panel

Background to the project

Ibstock Brick PLC identified a critical vulnerability in their production infrastructure; in the event of a mains power failure, critical production instrumentation and control systems would lose power. This loss would then render the company’s operations staff unable to monitor or control essential equipment, leaving them “blind” to real-time operational status.

Such a condition can be incredibly problematic for business operations, and may lead to:

- Inability to safely shut down or stabilise production processes

- Damage to equipment or products

- Increased safety risks to personnel

- Extended production downtime

- Regulatory or environmental compliance breaches

The Interpanel solution

Risk assessment

Firstly, Interpanel performed a detailed risk analysis to identify all affected systems and quantify potential impacts. We were then able to prioritise the most critical control and instrumentation systems for mitigation.

Install Uninterruptible Power Supply (UPS) Systems

Following the detailed risk assessment, we deployed industrial-grade UPS systems for Ibstock’s critical control panels, PLCs, SCADA servers, HMIs, and network infrastructure. We also ensured there was sufficient battery capacity for safe shutdown or transition to backup generation.

Immediate results

As a result of the work carried out by Interpanel, Ibstock Brick can now:

- Maintain operational visibility during outages. Installing UPS and backup systems ensures critical control and monitoring systems remain powered. Operations staff can also continue to see real-time equipment status and take informed actions during a power outage.

- Minimise production downtime. Quick response and system continuity during power loss prevents unnecessary halts and reduce restart times, which means minimal production downtime for the team. Preserving control also allows for a controlled, staged shutdown if needed.

- Prevent equipment damage. Uncontrolled shutdowns can damage sensitive production machinery. Continuous monitoring and control help prevent this risk.

- Improve safety for staff. Real-time visibility also reduces the risk of accidents or unsafe conditions when automated safety mechanisms are disabled.

- Protect product quality. Ongoing control of key processes prevents spoilage or defects in bricks during the power interruption.

At Interpanel, our team of TUV-certified functional safety engineers bring expertise in upgrading electrical control panels and adapting existing systems to match the changing demands of your operation.

Whether you’re scaling up, incorporating new technologies, or enhancing safety standards, we provide intelligent, future-focused solutions that will keep your systems running at peak performance.